What Is Laser Shearography?

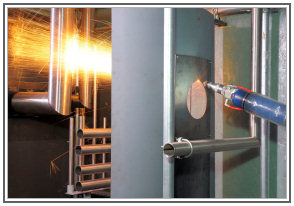

Laser shearography is an advanced non-destructive testing (NDT) technique that uses laser interferometry to detect hidden flaws within materials and components. Instead of relying on physical contact or simple visual inspection, it provides a full-field, high-resolution image of surface and subsurface defects. The process involves projecting laser light onto a surface, then applying a small amount of stress through heat, vacuum, or mechanical load. Any underlying defects cause microscopic deformations, which the shearography system captures as fringe patterns. These patterns clearly reveal the location and severity of faults such as delaminations, cracks, and disbonds.

How It Works

When a material is illuminated by coherent laser light, the reflected beams create an interference pattern that represents the surface’s optical characteristics. By comparing two states, before and after stress is applied, laser shearography detects even the smallest changes in the surface structure. The result is a real-time visualisation of strain anomalies that indicate internal damage. Because the system captures data from an entire area at once, large surfaces can be inspected quickly and accurately.

Industrial Applications

Laser shearography has proven invaluable across a range of industrial and manufacturing sectors. It is widely used for:

- Aerospace and Defence: Inspecting composite aircraft panels, bonded joints, and honeycomb structures for delamination or debonding.

- Automotive and Motorsport: Testing lightweight carbon fibre components, tyres, and bonding integrity in structural parts.

- Wind Energy: Evaluating turbine blades and composite sections for subsurface defects that could affect performance.

- Rubber and Composites Manufacturing: Ensuring quality control during production without interrupting workflow.

Its ability to perform on-site, non-contact inspection makes it ideal for both laboratory testing and in-field maintenance.

Benefits of Using Laser Shearography

Compared with conventional NDT techniques such as ultrasonic or dye penetrant testing, laser shearography offers several key advantages:

- Full-field inspection: Captures large surface areas in a single measurement.

- High sensitivity: Detects minute subsurface defects invisible to the naked eye.

- Fast and efficient: Produces results in real time with minimal setup.

- Non-contact and non-destructive: No risk of damage to delicate materials.

- Vibration-tolerant: Can be used effectively in industrial or outdoor environments.

- Digital traceability: Results can be archived and compared for long-term monitoring.

Advancing Quality and Reliability

For industries where structural integrity and reliability are critical, laser shearography delivers a powerful, efficient, and precise inspection solution. By enabling early defect detection and reducing the need for rework, it helps manufacturers improve quality, extend component life, and maintain safety standards.

Laser Optical Engineering Ltd continues to lead the way in the development and application of shearography systems, supporting industries that demand the highest levels of precision and assurance in non-destructive testing.

UK Manufacturers – List of Industrial Manufacturers

Finding Our Way Directory

Expotural.com