At Laser Optical Engineering we have extensive experience in the area of Research & Development having worked on projects from both government and privately funded sources.

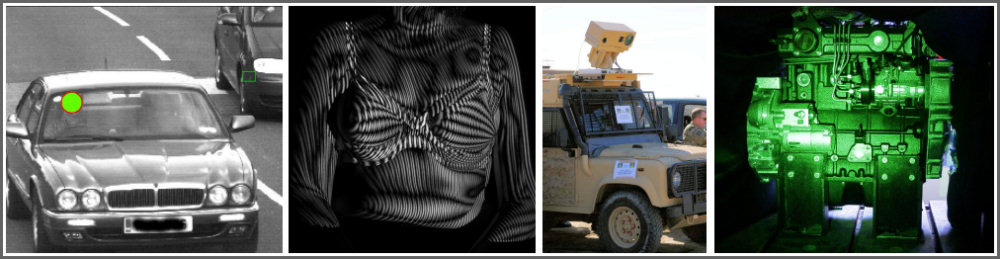

An example of this is our ExDtect which provides real-time stand-off explosive residue detection. The system can be remotely operated and provide automated warnings. The current system can detect Semtex and ammonium nitrate/fuel oil (AN/FO) based explosives. The ExDtect is continually being developed to expand its range of detectable explosives.

Other projects we have been involved in cover a wide range and include:

- Detection of buried objects

- Non-destructive testing using laser shearography of hidden defects in manufactured components

- Optical inspection and vibrational analysis of engine components

- Optical inspection, design and development of bras

- Laser induced fluorescence detection of trace substances, such as explosives and bodily fluids.

- Multispectral imaging for the counting of people in vehicles

We take innovative ideas from concept all the way through to production.

Previous collaboration with industry and academia have resulted in:

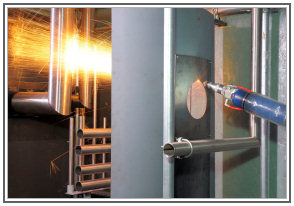

- Sensor and monitoring systems for improving efficiency and quality of laser welding processes through closed loop control.

- Surface Crack, Universal Total Inspection and NDT Surface Examination (SCRUTINISE) project to develop a novel system to detect surface cracks.

- 3D copper tracks/circuitry production on 3D aerospace structures, using lasers to write in to the copper.

Our project teams have complete autonomy to deliver results. At their disposal is a pool of resources; creative, talented engineers with an in-depth knowledge of industry and regulation, and access to extensive laboratories and prototyping facilities.