Laser Safety, Laser Shearography, Non-Destructive Testing

Laser Optical Engineering Ltd (LOE) is an ISO9001 certified company, specialising in the development of innovative and bespoke laser-based imaging products and services including laser safety and the non-destructive testing of materials and components. Established in 1996 as an independent spin-out company from Loughborough University, we are a customer focused company who pride ourselves on an ability to turn theoretical ideas into commercial products which can be used in real-life situations.

Based near East Midlands Airport, LOE works with various industries, including aerospace, maritime, nuclear, transport and communications along with various research institutions. Alongside bespoke projects, LOE designs, manufactures and installs a range of laser safety equipment, provides laser consultancy, optical inspection and training services and designs and manufactures Diffractive Optical Elements (DOE’s) to your requirements.

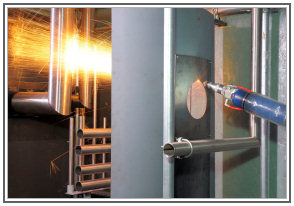

Our Defect Dtect system, developed in our R & D facility, is a small, modular and versatile laser shearography unit providing whole-field, non-contact, non-destructive testing for rapid wide-field inspection of composites, bonded structures and other advanced materials. The Vac Dtect is our handheld laser shearography system utilising a variable vacuum to provide non-destructive testing, rapid defect detection and optical inspection of materials.

Coming out of our in-house R & D facility, our experienced engineers are able to review your technical challenges and advise on solutions to any issues you may have. We offer a complete service from providing an initial proposal of ideas including costs and running through to the installation of your new piece of equipment with end-user training.

Our ExDtect is an explosive detection unit capable of remotely detecting Semtex and ammonium nitrate/fuel oil (AN/FO) based explosive residue.

Professor John Tyrer is Managing Director of LOE and has 40 years of experience in industry and academia. He divides his time between LOE and the Wolfson School of Mechanical, Electrical and Manufacturing Engineering at Loughborough University.